-

A

-

A

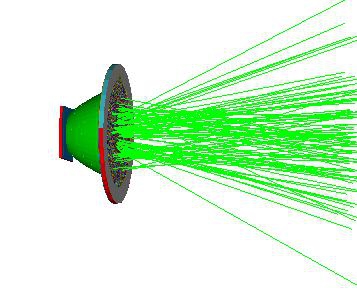

Optical Design:We have a lot of experience in imaging and non-imaging optical design. Especially in the LED lighting lens, we can simulate the final result which is near the real injected lens. We have patent structure to ensure the minimum chromatic deviation.

Mold Design & Manufacturing:We design the mold with considering the mold flow and form compensation skills. That means we can deliver the product in a short time without modifying the mold for n times.

Plastic Injection:All our plastic lens are injected from Fanuc optical grade injection machine which produce stable and precision optical lens. Our operating engineers have ample experience in complicated structure of optical plastic injection.

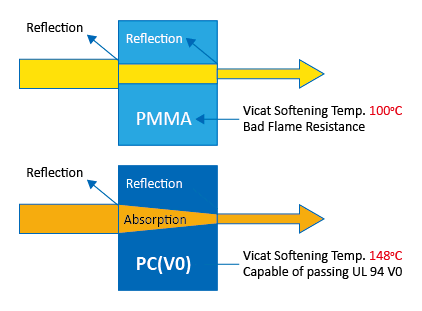

Design capability of using(PC:UL94V-0)

PC:Capable of passing UL 94 V0 grade to have better flame resistance, but absorb the light passing through it.PMMA:No light absorption lead to higher transmittance, but very bad flame resistance.We use the PC with UL94 V0 grade to make lens which has nearly the same high output performance as using PMMA.

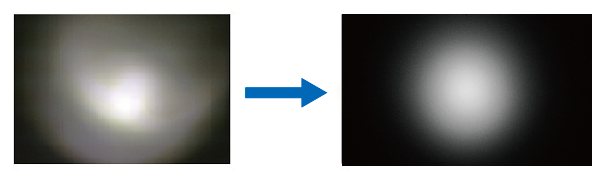

Lower Chromatic Aberration

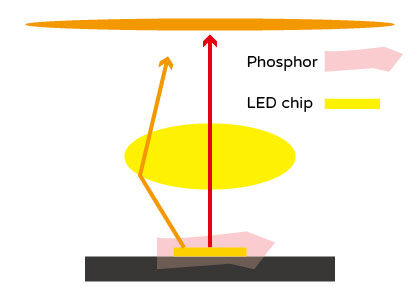

The phosphor on the LED can change the light to different color. But the light path difference that light pass through the phosphor will induce color shadings.

With the lens to converge the light will lead to more heavier color shading.

We have patent structure on the lens to make smaller color shading .

-

A

-

A

-

A

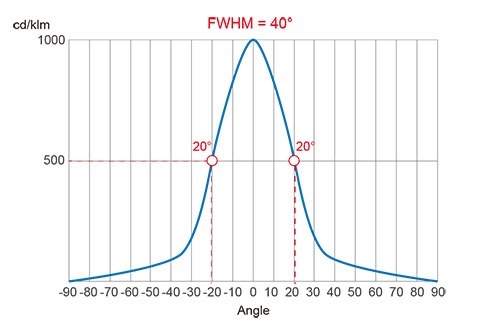

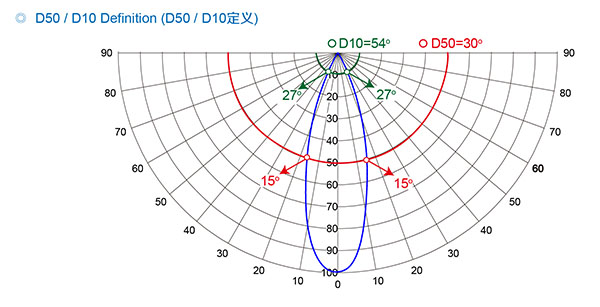

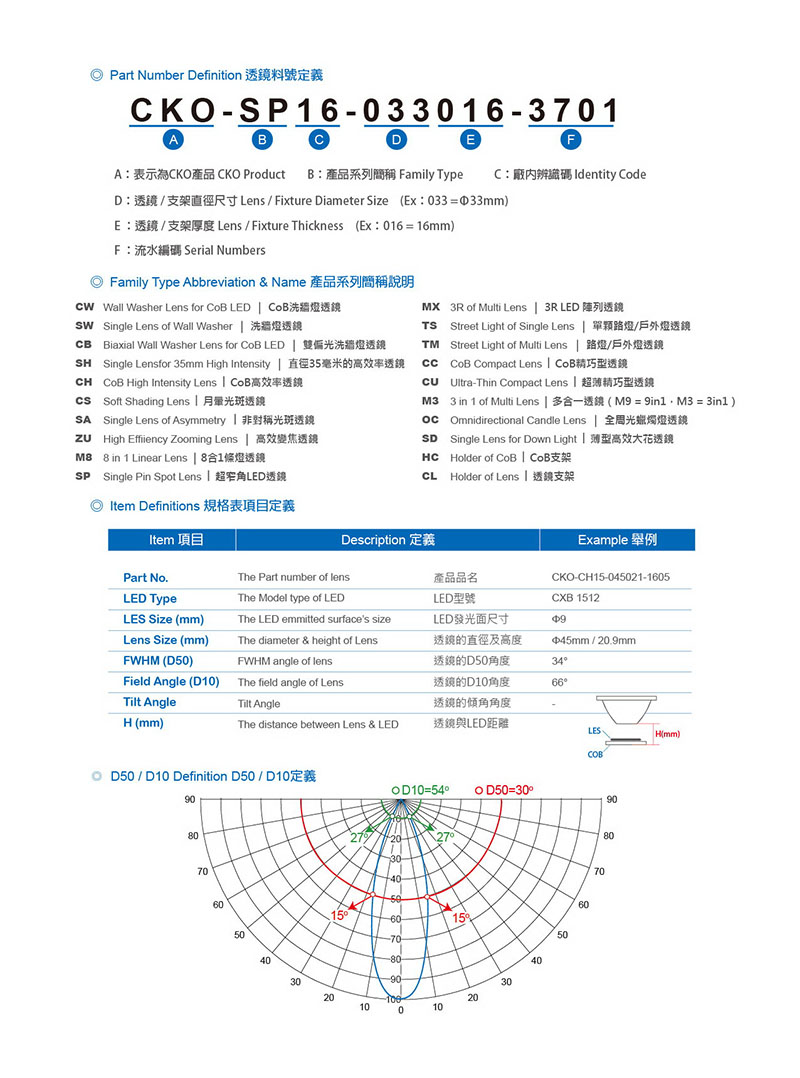

The definition of the beam angle in CKO’s lens is FWHM(Full Width at Half Maximum) , which is defined by Energy Star, 50% light intensity (D50,half angle).But some customers , especially in China, would like to use D10 to define their lens. It is also called D10. Please refer to the drawing to see the difference.CKO will modify its standard lens list later to show both half angle (D50) and full angle (D10) later.

FWHM ( Full Width at Half Maximum) : the angle that cd is greater than 50% of the Max cd. Also named D50.

Full Angle (D10) : The angle that cd is greater than 10% of the Max cd.

Most of them were asked to define in the light pattern.

-

A

-

A

Yes , we have patent on our lens to protect our customers for using them.

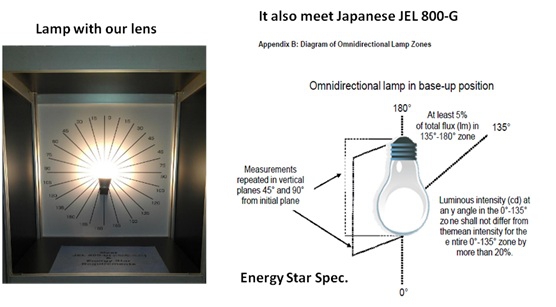

We have patent structure that can guide light backward . This can be used to the omni-directional lamp or candle light ,and those who need the light turn to very big angle.The phosphor on the LED can change the light to different color. But the distance that light pass through the phosphor will induce color shadings.

With the lens to converge the light will lead to more heavier color shading.

We have patent structure on the lens to make smaller color shading .

-

A

Currently only CREE’s MTG ,Nichia’s 283,and LG’s MCP COB with the bulb cap we provided can pass the energy star omnidirectional spec..

If you change the LED or the bulb cap, then it may not pass the energy star’s spec. but pass the JEL 800-G.

If you consign a LED , we will either slightly change the lens shape ,or change different bulb cap to meet that spec.

-

A

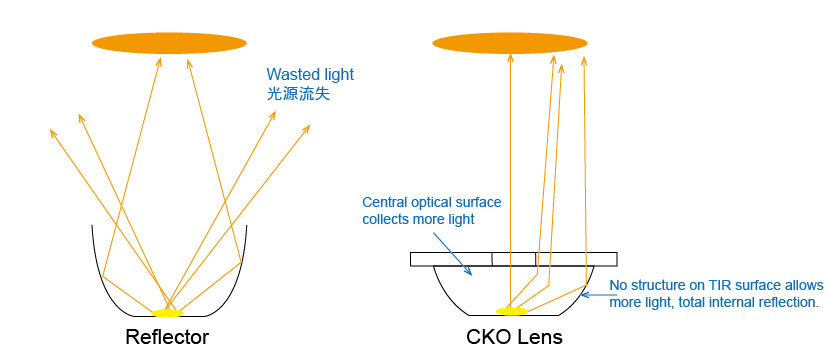

TIR is one of the few physical phenomena, which can produce 100% efficiency. Coated reflectors are only as efficient and durable as the coating; no coatings or plating are required on TIR designs;and reflectors are not able to utilize/control the on-axis light.

-

A

1.CKO's patent structure is not like common optics that is on the TIR surface 2.Traditional Reflector 70~50% reflectance